Foam product heat stabilizer LX-1030

If you are interested, please call directly for more effective communication. We will provide you with exclusive VIP service!

Classification

Keywords

Foam product heat stabilizer LX-1030

If you are interested, please call directly for more effective communication. We will provide you with exclusive VIP service!

Classification

Keywords

- Description

-

Polyvinyl chloride inhibits the release of HCl from passivated PVC resin molecules during production and processing, thereby preventing material degradation and carbonization. It is an essential additive in PVC processing. It effectively solves the problem of thermal fracture of the PVC molecular structure, achieving stability, weather resistance, and flame retardancy. This product complies with EU ROHS directive requirements and has been certified by SGS, providing good thermal stability, sufficient color retention, and excellent flow performance.

Product Advantages

❊ Non-toxic and environmentally friendly, certified by SGS, meeting export standards.

❊ Good foaming ratio, with a whitening effect on white foamed products.

❊ Ideal lubrication system and stable system, improving mold release cycles.

❊ Suitable for fast molds and high-speed mold use, increasing production efficiency and reducing production costs.

Scope of Application

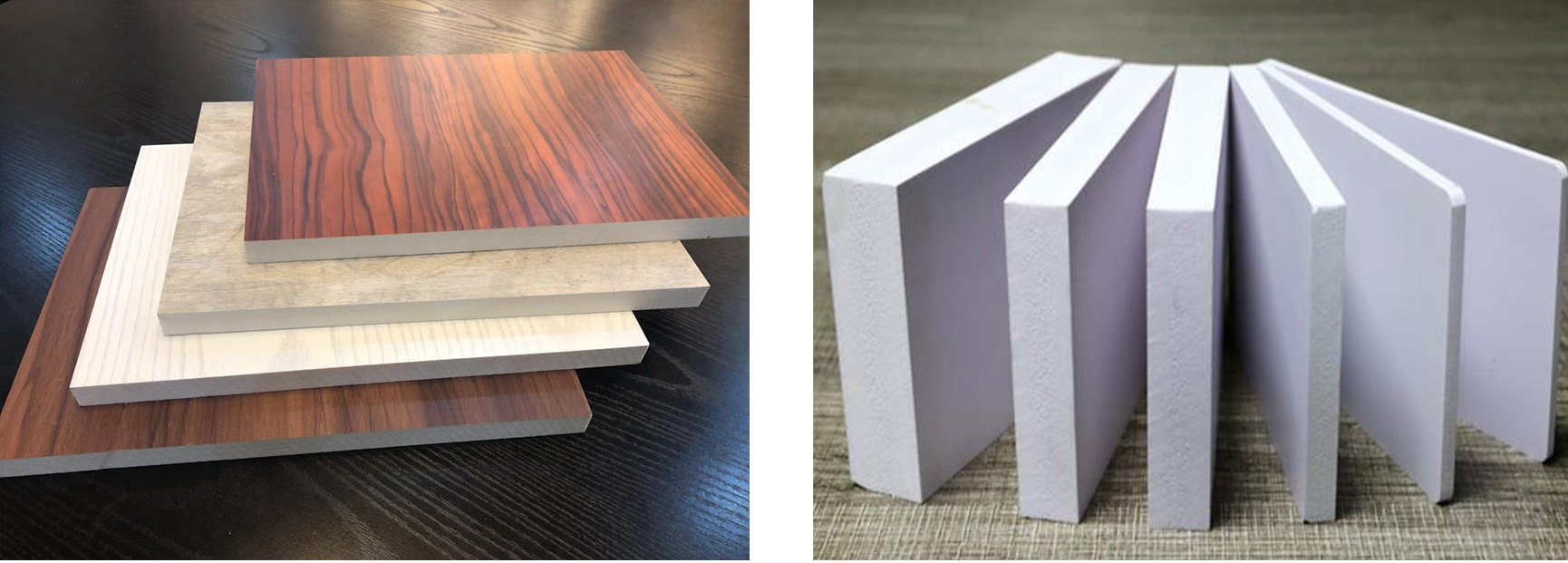

Various low-foaming, high-foaming, rigid, and semi-rigid PVC products, including foamed wall panels, wood veneer panels, advertising boards, cabinet boards, carving boards, foamed molding, and blinds.

Application Products

Powered by

The company's professional technical team will provide you with production formulas, optimize production processes, and help you improve product quality and reduce costs. Tell us your needs, and we will provide you with customized solutions!

Storage and Transportation

❊ 20KG and 25KG open PP bags with inner bags or kraft paper bags;

❊ 500KG and 1000KG ton bags; fumigated or non-fumigated pallets;

❊ Products should be stored in a cool, dry environment, with a shelf life of up to two years. After two years, they can continue to be used only after passing inspection.

Research Equipment

UV ultraviolet aging test chamber

Static oven

Tensile Testing Machine

Gas Chromatograph

FAQ

Q:

What are the main products of your company?

A:

Q:

Can your company mail samples?

A:

Q:

Can your company help clients solve technical problems?

A:

Q:

How long has your company been in this industry?

A:

Q:

What is the warranty period for your company's products?

A:

Q:

What is the delivery cycle of your company?

A: