Super strong melt strength type LX-90

If you are interested, please call directly for more effective communication. We will provide you with exclusive VIP service!

Classification

Super strong melt strength type LX-90

If you are interested, please call directly for more effective communication. We will provide you with exclusive VIP service!

Classification

- Description

-

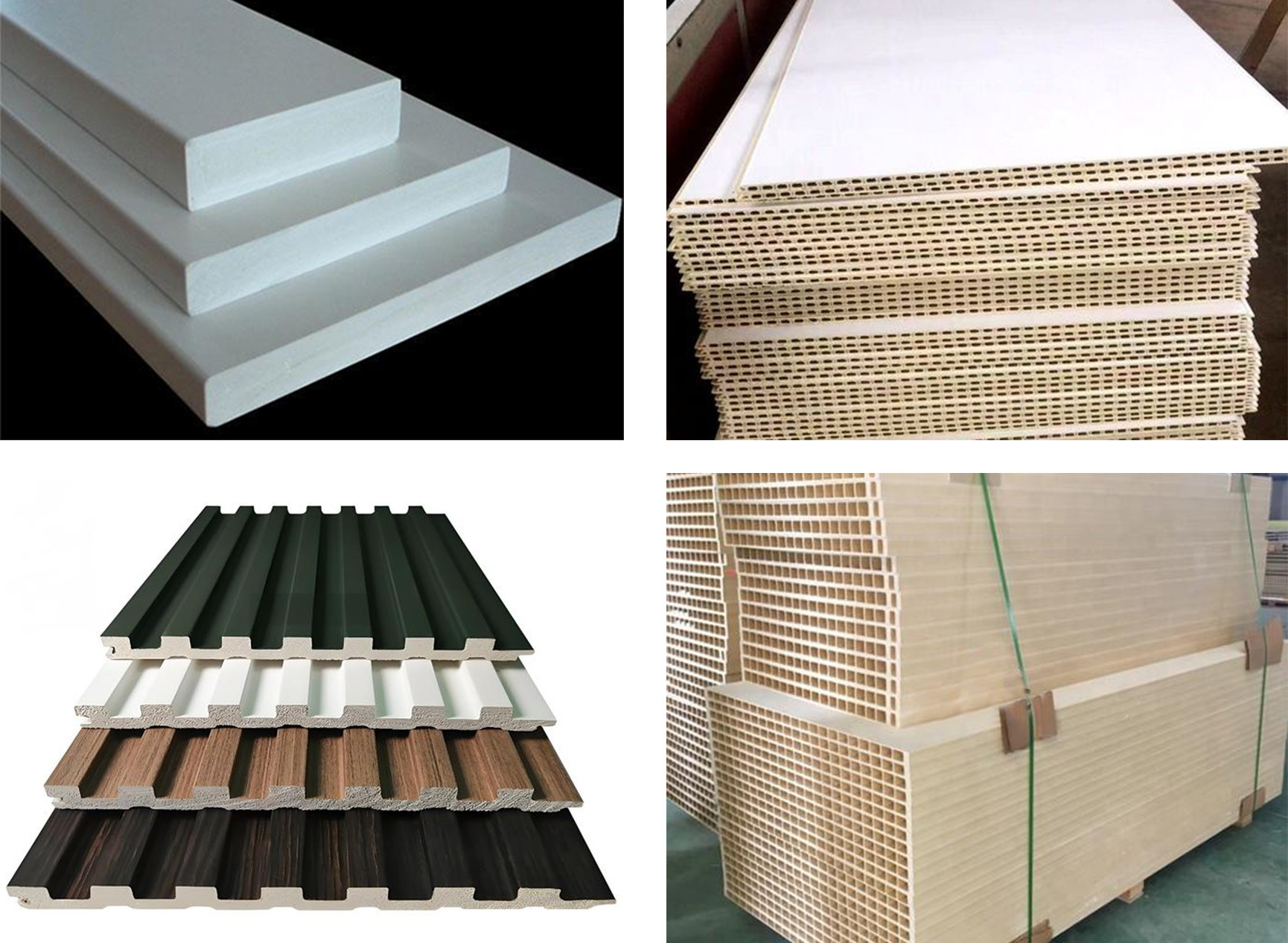

The super plasticizing high molecular weight PVC foaming regulator lx-90 LX-930 is a fully acrylic PVC high molecular weight foaming regulator independently developed by the company to meet the increasing demand for PVC extruded micro-foaming materials; it can be applied in various foamed profiles, pipes, sheets, wood-plastic, ceiling panels, wall panels, and large-diameter corrugated pipe products; the ultra-high molecular weight lx-90 LX-930 is prepared from acrylic monomers through an ultra-low temperature emulsion polymerization process, with a high content of hard monomer components, belonging to random copolymers, with ultra-high molecular weight and linear distribution, and can be widely used in billboards, high-filled foamed profiles, bathroom cabinet boards, density boards, foamed thick boards, extra-thick boards, wood-plastic, construction templates, etc. The product is a white powder, insoluble in water and ethanol, and can dissolve or swell in ethers, ketones, and chlorinated hydrocarbons. The product meets the hygiene standard GB9681.

Product Advantages

❊ High molecular weight products can promote the low-temperature melting of PVC, effectively changing the rheological properties of PVC products.

❊ Ultra-high molecular weight and ultra-strong melt strength can effectively prevent the fusion of bubbles and the rupture of bubble walls, resulting in a uniform and dense bubble structure, with low product density.

❊ Prevent bubble melting and rupture.

❊ The high content of methyl methacrylate monomer in ultra-high molecular weight products has a glass transition temperature close to polymethyl methacrylate (acrylic). It has excellent compatibility with PVC, providing the PVC melt with excellent melt strength while the foaming agent releases gas when heated, and has strong and stable coating ability.

❊ Significantly improves the thermal elongation and elasticity of PVC products.

Model and PerformanceModel

Viscosity η at 25°C

Weight average molecular weight

Molecular weight distribution

Apparent density (g/cm²)

Volatile content (%)

Screen residue (30 mesh %)

LX-90

13.50-16.50

(9.500-10.900)×106

≤1.100

0.45±0.10

≤1.3

≤2.0

LX-930

13.50-16.50

(9.500-10.900)×106

≤1.100

0.45±0.10

≤1.3

≤2.0

Powered by

Our professional after-sales team will provide you with production formulas, optimize production processes, help you improve product quality, and reduce costs. Tell us your needs, and we will provide you with customized solutions!

Applications Packaging and Transportation

Packaging and Transportation

❊ 20KG and 25KG PP open bags with inner bags or kraft paper bags;

❊ 500KG and 1000KG ton bags; fumigated or non-fumigated pallets;

❊ Products should be stored in a cool, dry environment, with a shelf life of up to two years. After two years, they can continue to be used only after passing inspection.

Research Equipment

UV ultraviolet aging test chamber

Static oven

Tensile Testing Machine

Gas Chromatograph

FAQ

Q:

What are the main products of your company?

A:

Q:

Can your company mail samples?

A:

Q:

Can your company help clients solve technical problems?

A:

Q:

How long has your company been in this industry?

A:

Q:

What is the warranty period for your company's products?

A:

Q:

What is the delivery cycle of your company?

A: